Understanding Surf Etiquette for Beginners at Crowded Breaks

January 20, 2025

Diaper Bag Essentials for Winter Weather

January 22, 2025Cutting Hardened Steel With Plasma: Limitations and Techniques

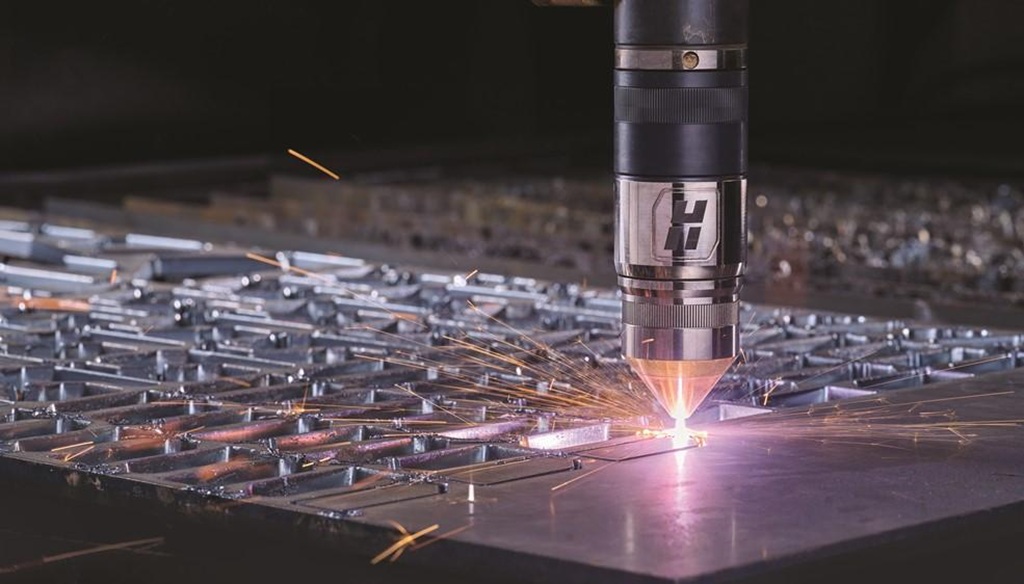

When it comes to tackling tough materials like hardened steel, few methods are as popular as plasma cutting. Known for its precision, speed, and ability to slice through metals of varying thickness, plasma cutting is a game-changer in industrial and workshop settings alike. However, this powerful technique comes with its own set of challenges, especially when dealing with hardened steel. Why? Because hardened steel isn’t just any steel – it’s been treated to withstand wear, heat, and pressure, making it notoriously difficult to cut cleanly and efficiently.

Before diving into the intricate limitations and advanced techniques for plasma cutting hardened steel, it’s worth noting that this topic has sparked significant debate among experts. If you’re looking to explore Thenewargument for deeper insights, you’ll find expert opinions and actionable advice to enhance your understanding. Let’s break this down step by step and discover how to make plasma cutting work effectively for hardened steel.

Table of Contents

ToggleWhat Makes Hardened Steel So Difficult to Cut?

Hardened steel is a product of heat treatment processes like quenching and tempering, which increase its hardness and strength. This material is prized for its durability, often used in industrial tools, automotive parts, and machinery components. Yet, these same properties create unique challenges during cutting.

- High Thermal Conductivity Resistance: Hardened steel disperses heat unevenly, making it prone to warping when exposed to high temperatures.

- Resistance to Abrasion: Its enhanced toughness means traditional cutting methods can wear out tools quickly.

- Thicker Variants: For industrial use, hardened steel often comes in thicknesses that demand more power and precision from cutting equipment.

Understanding these challenges is key to determining whether plasma cutting is the right tool for the job or if alternatives like a torch or mechanical saw might be better.

How Plasma Cutting Works: A Quick Overview

Plasma cutting uses an ionized gas stream, or plasma, to generate extreme heat capable of melting and slicing through metal. A plasma cutter directs a focused jet of this plasma through a high-speed nozzle, creating clean and precise cuts. The combination of compressed gas and electricity makes this method incredibly efficient for cutting conductive materials like steel, aluminum, and stainless steel.

While plasma cutters are a go-to for many professionals, the high precision they offer can sometimes fall short when working with hardened steel due to the material’s properties.

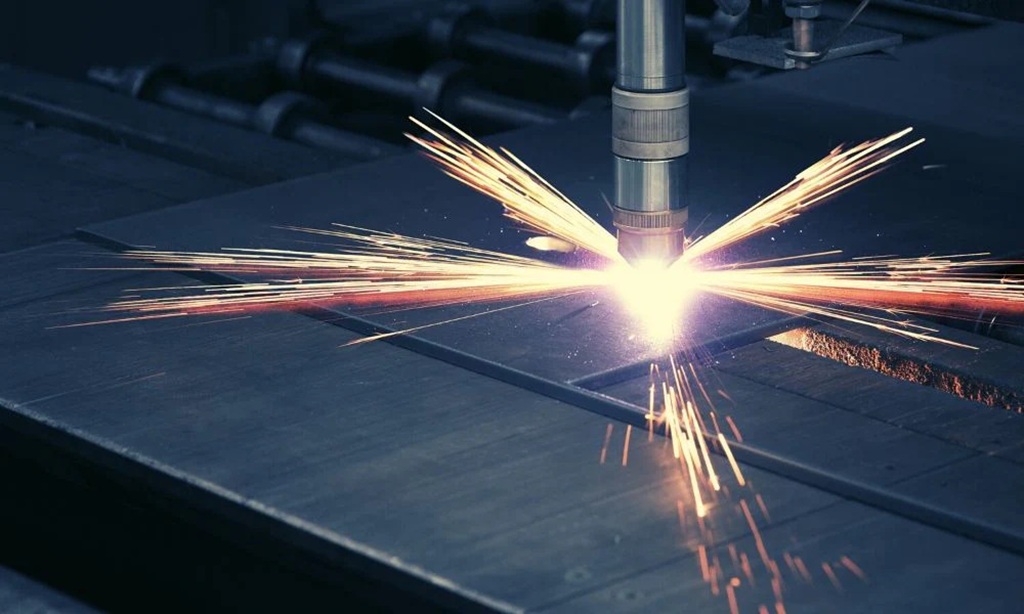

Key Limitations of Cutting Hardened Steel With Plasma

Despite its impressive capabilities, plasma cutting has some notable drawbacks when working with hardened steel. Let’s explore these limitations in detail:

- Heat-Affected Zones (HAZ):

Plasma cutting generates intense heat, which can create a heat-affected zone along the cut edge of hardened steel. This zone may weaken the steel’s properties, potentially compromising its structural integrity. - Loss of Precision on Thick Steel:

While plasma cutters excel at cutting thinner metals, they struggle with ultra-thick hardened steel. The plasma arc may lose its focus, leading to jagged edges or incomplete cuts. - Increased Wear on Consumables:

Hardened steel’s toughness accelerates wear on plasma cutter components like electrodes and nozzles, increasing maintenance costs over time. - Potential Warping:

Due to the high temperatures involved, thinner sections of hardened steel may warp or distort during plasma cutting, especially if not cooled properly. - Gas Selection Challenges:

Plasma cutting relies on specific gases like oxygen, nitrogen, or argon. Choosing the wrong gas for hardened steel can reduce efficiency and compromise the quality of the cut.

Techniques for Cutting Hardened Steel With Plasma

Despite the challenges, skilled operators can achieve excellent results with plasma cutting by using the right techniques and tools. Below are practical tips to optimize your plasma cutting process:

- Use a High-Powered Plasma Cutter:

To handle the density of hardened steel, invest in a high-performance plasma cutter capable of delivering the necessary amperage. Machines with at least 60 amps are recommended for thicker steel. - Optimize the Cutting Speed:

Finding the right cutting speed is crucial. Cutting too slowly can cause excessive heat buildup, while cutting too fast may result in uneven edges. Adjust your speed based on the thickness and hardness of the steel. - Choose the Right Gas Combination:

Using the correct gas mixture can make a significant difference. For hardened steel, oxygen or nitrogen is typically preferred for clean cuts and minimal dross. - Use Proper Cooling Methods:

To minimize warping and maintain the steel’s integrity, apply cooling techniques such as water-cooled tables or spraying water mist on the cutting area. - Maintain Consumables:

Regularly inspect and replace consumables like electrodes and nozzles to ensure consistent performance and avoid costly downtimes. - Consider Preheating:

Preheating hardened steel before plasma cutting can help reduce heat-affected zones and improve cut quality. A handheld torch or induction heater works well for this purpose.

Plasma Cutter vs Torch for Hardened Steel

When deciding between plasma cutting and alternative methods like a torch, it’s essential to weigh the pros and cons of each. Plasma cutters are known for their precision and speed, while torches excel in cutting thicker materials without compromising durability. If you’re curious about the detailed differences, click on https://thenewargument.com/torch-vs-plasma-cutter-a-detailed-comparison/.

Plasma cutters are best for intricate cuts and reducing material waste, but torches may outperform them in cost-efficiency for thicker hardened steel.

The Role of Safety in Plasma Cutting

Safety cannot be overstated when working with plasma cutters, especially on hardened steel.

Here are critical precautions:

- Wear protective gear like gloves, helmets, and flame-resistant clothing.

- Ensure proper ventilation to avoid inhaling fumes.

- Avoid working in damp conditions to reduce the risk of electric shocks.

- Keep a fire extinguisher nearby in case of sparks or flammable material igniting.

Related: Are Digital Measuring Tapes More Accurate Than Traditional Ones?

Applications of Plasma Cutting Hardened Steel

Plasma cutting is widely used in industries such as:

- Automotive Manufacturing: Cutting hardened steel for vehicle parts and chassis.

- Tool Production: Shaping hardened steel into tools like wrenches and drill bits.

- Construction: Fabricating beams, joints, and supports from hardened steel.

Conclusion

Cutting hardened steel with plasma is undoubtedly a challenging task, but with the right equipment, techniques, and knowledge, it can yield highly precise results. By understanding the limitations and leveraging advanced methods like proper cooling, gas selection, and consumable maintenance, operators can overcome the hurdles posed by this tough material.

Whether you’re a professional metalworker or a hobbyist, mastering plasma cutting for hardened steel is a valuable skill that can open up endless possibilities in your projects. So, arm yourself with the right tools and techniques, and dive into the rewarding world of plasma cutting.

FAQs

How thick can plasma cutters cut hardened steel?

Modern plasma cutters can slice through hardened steel up to 1-2 inches thick, depending on the machine’s power rating.

Does plasma cutting damage hardened steel?

While plasma cutting may create a heat-affected zone, proper cooling methods can minimize damage and preserve the steel’s properties.

Is plasma cutting cost-effective for hardened steel?

Yes, plasma cutting is cost-effective for medium-thickness hardened steel, but maintenance costs can rise due to wear on consumables.

Can you use a plasma cutter for precision cutting?

Absolutely! Plasma cutters are ideal for precise, intricate cuts on conductive materials, including hardened steel.

Related: Do Solar Panels Emit Radiation? Unpacking the Truth About Solar Energy and Your Health

What gases are best for plasma cutting hardened steel?

Oxygen and nitrogen are commonly used for their efficiency in producing clean cuts on hardened steel.

Is plasma cutting safer than a torch?

Yes, plasma cutting is generally safer due to fewer open flames, but operators must still follow safety protocols.